Mastering the Details: Our Process in Action

Mastering the Details: Our Process in Action

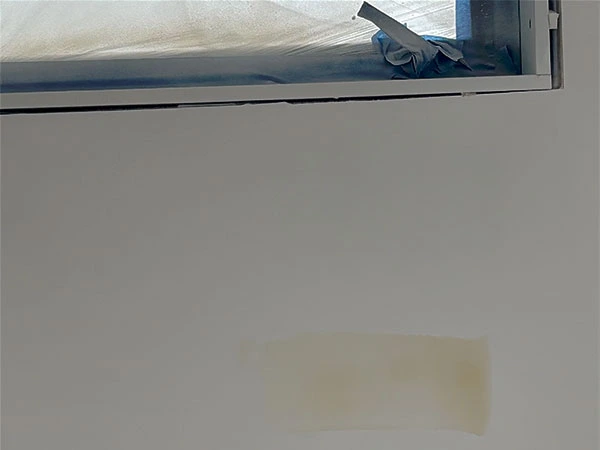

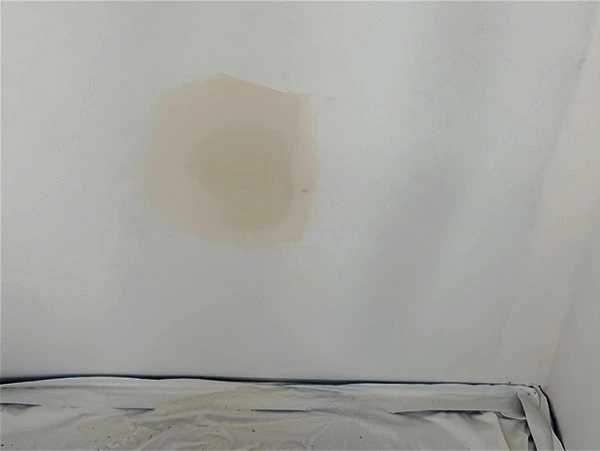

Our first inspection revealed that the existing GIB stopping and plasterwork were not up to the standard required for a top end of level 4 finish. To proceed would have been to compromise the entire project. This required immediate intervention.

Understanding the critical time pressure

Understanding the critical time pressure, our specialist plasterers committed to 12-hour days and weekends, meticulously re-working walls and ceilings to create the flawless substrate we required. This wasn't a setback; it was the essential first step to guaranteeing a world-class result.

With the foundation set, our systematic preparation began:

- Full Prime:

All walls, ceilings, and frames were sealed with Dulux 1 Step Primer. - Secondary Fill:

We then undertook a second, detailed plastering pass to eliminate any remaining imperfections.

Our systematic preparation began:

- Perfect Sanding:

Every plastered and primed surface was then sanded to a smooth, uniform finish.

Project presented the next challenge

The project's sequencing presented the next challenge. The walls and ceilings were ready for their top coats, but skirting boards and architraves had not yet been installed. We adapted, painting the broad walls and ceilings first. Once the trim was fitted against our finished walls, the demand for precision was absolute.

Surgical masking process

Our team executed a surgical masking process across the entire house. Each piece of trim and every door was then taken through an exhaustive process: sand, prime, fill, sand, spot-prime, and a final light sand before receiving two flawless top coats.

To achieve a finish

To achieve a finish that is impossible with a brush and roller, all doors were removed and transported to a dedicated spray booth we constructed on-site, ensuring a perfect, factory-like enamel.

Finally, in a fast-paced environment

Finally, in a fast-paced environment with multiple trades rushing to meet the deadline, protecting the final finish is paramount. Our team remained vigilant and flexible, returning to completely repaint six different walls that were damaged by other trades during the final push. Our commitment was to hand over a perfect home, and we did whatever it took to honour that.